Childcare equipment and children’s furniture must meet strict safety, quality and performance requirements. Manufacturers and retailers of products designed and intended for use by parents and carers must navigate a complex array of standards and regulations. Noncompliance poses a risk to end users, and to the supply chain.

What are the benefits of SGS’s juvenile product and childcare article services?

- Protect of consumers from potential harm

- Protect your brand

- Minimize the risk of costly recalls and customer returns

- Consumer recognition that products meet or exceed the applicable safety standards and regulatory compliance requirements

- Build consumer confidence

Consulting and training, safety/risk assessment and regulatory compliance

During concept, design and pre-production.

Let us take the strain out of product development. With unrivaled knowledge and experience our experts can provide you with regulatory updates and monitoring services, as well as interpretation of new and revised standards and regulations. We can then review your product concepts, designs and prototypes to help make sure you develop compliant product from the outset taking corrective actions early on to save you time and money.

We ensure that your product planning takes into account:

- Applicable standards

- Foreseeable use and misuse

- Foreseeable risks

- Designing hazards out and safety in

In the design phase, we can develop customized product safety and performance specifications, as well as design evaluations, manufacturing feasibility studies and risk assessments on your juvenile products and childcare articles.

In readiness for production, our experts can assist you with product assembly/use instructions and market-specific labeling and marking.

Factory and social audits

Before production and ongoing.

Ensure that the factory you have selected will be able to deliver products with required safety and regulatory compliance, to the expected quality and on time.

Our global network of auditors conducts factory audits to evaluate and certify quality management systems, social accountability, environmental, manufacturing process, technical capability and capacity.

Testing

Before and during production.

International standards, product- or client-specific protocols and internal protocols, we can test your juvenile and childcare products against them all. We’ll check performance and construction integrity, quality and safety with our wide range of:

- Physical and mechanical tests

- Chemical tests

- Material tests

- Flammability tests

- Food contact tests

- Marking and labeling reviews

- International Safety Standards Reference Guide for the Juvenile Products Industry

Our test capabilities worldwide, cover the full range of juvenile products.

- Cleaning & hygiene

- Changing tables

- Bath thermometers

- Infant bath seats and tubs

- Early learning

- Infant swings

- Infant walkers

- Stationary activity centers

- Feeding & accessories

- Cutlery sets and feeding/drinking equipment

- Baby bottles and teats/nipples

- Soothers (dummies)/pacifiers

- Soother/pacifier holders

- Physical protection

- Safety harnesses

- Safety gates and enclosures

- Portable bed rails

- Play yards (play pens)

- Seating

- Highchairs and children’s chairs

- Hook-on chairs

- Booster seats

- Infant bouncer seats and reclined cradles

- Infant floor seats

- Transport

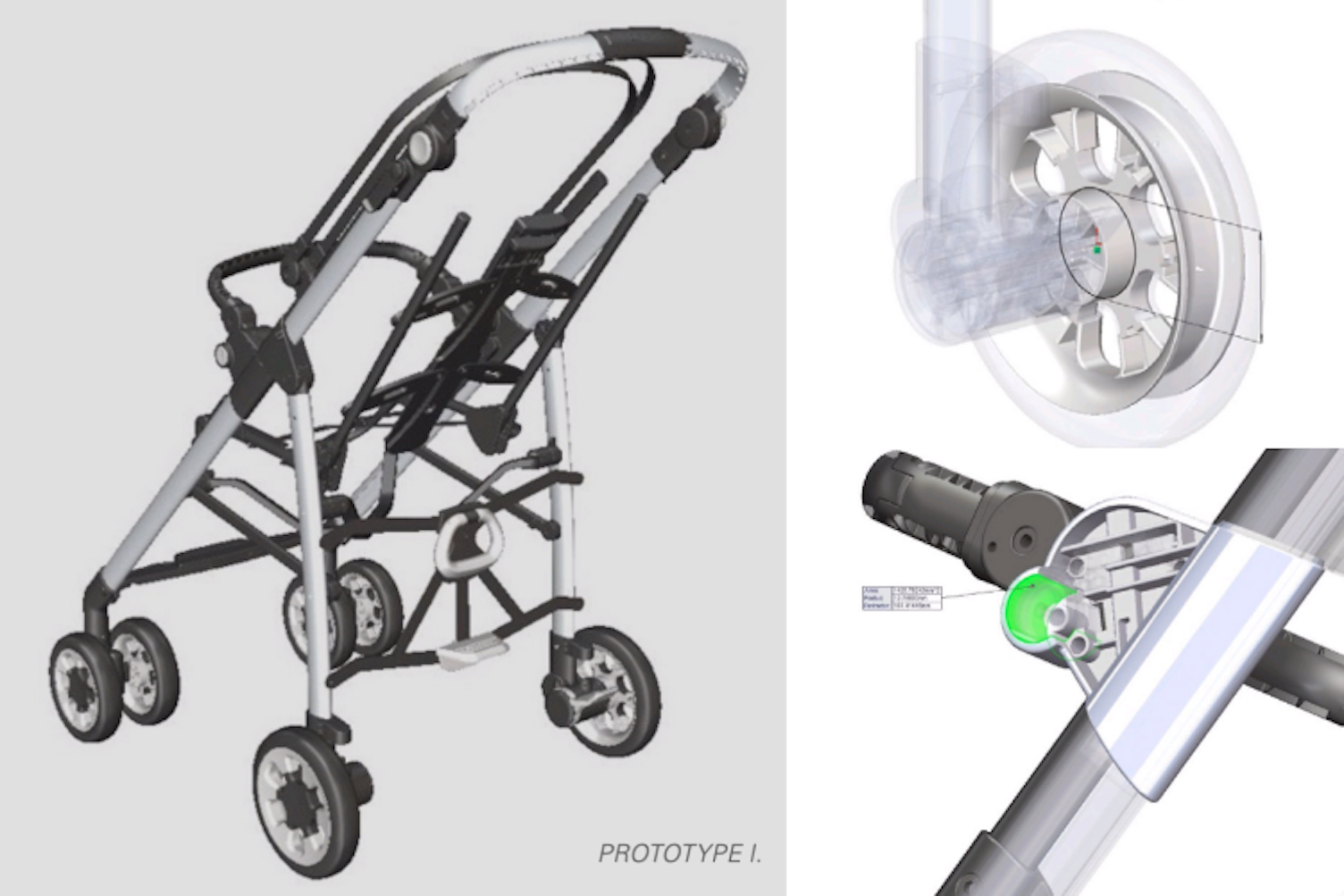

- Prams and strollers

- Baby carriers and slings

- Child seats for cycles

- Car seats and car booster seats

- Child restraint systems

- Sleeping

- Cots and cribs (non-full and full size)

- Bassinets and cradles

- Children’s furniture

- Carry cots and stands, bedside sleepers

- Toddler beds

- Crib mattresses

- Textile sleep products

Inspection

Before, during and after production/pre-shipment, and at point of sale.

Ensure the quality of your products is maintained and that suppliers can fulfil their contracts, with inspections. Our global network of inspectors provides checks and verification at every stage of production, including:

- Initial production check (IPC)

- During production inspection (DUPRO)

- Final random inspection (FRI)

We also offer ‘mystery’ shopping services to check product compliance at the point of sale.

Pre-shipment testing (PST)

Before shipment.

Ensure the compliance of products before they are dispatched to their destination with our random testing, after production, to check the overall compliance of products and production processes. This service includes:

- Packaging verification

- Product information and claims verification

- Testing of products’ critical safety points

GS Mark certification

Before shipment.

Demonstrate product safety with the voluntary Geprüfte Sicherheit (GS) mark. This mark denotes that a product complies with the German Product Safety Act.

Products tested:

- Baby carriers

- Cots and folding cots

- Cribs and cradles

- Furniture for babies and children

- Highchairs

- Strollers

Product characteristics tested:

- Physical safety

- Mechanical safety

- Chemical properties

- Hazardous material use

- Manufacturing

GS mark certification tests can be carried out in our Aix en Provence and Shanghai laboratories under the approval of our German certification body, SGS Institut Fresenius.

JPMA certification

Before shipment.

Reduce testing duplication and redundancy with certification from the Juvenile Products Manufacturers Association (JPMA). The JPMA program is based on conformance with ASTM, Federal regulations (including CPSIA) and state-specific requirements, as well as the requirements of some key retailers.

We are a JPMA approved partner testing laboratory. All our JPMA approved laboratories are also CPSC approved for CPSIA testing. Certified products can display the JPMA Certification Seal (on the product and its packaging). This mark is well regarded by consumers as it shows that products have met the highest safety standards. More information is available at JPMA Certification.

Product categories within scope:

- Baby changing products

- Infant floor seats

- Baby monitors

- Infant incline sleep products

- Bassinets and cradles

- Infant swings

- Bedside sleepers

- Infant walkers

- Booster seats

- Infant bath seats, bathtubs and bathers

- Carriages and strollers

- Play yards and non-full size cribs

- Child safety locks and latches

- Portable bed rails

- Children’s folding chairs

- Portable hook-on chairs

- Crib mattresses Full Expansion gates and expandable enclosures

- Rocker and bouncer seats

- Side baby cribs

- Stationary activity centers

- Handheld infant carriers

- Soft infant carriers and frame child carriers

- Highchairs

- Toddler beds

SGS green marks

Before shipment.

Verify product claims and meet consumer demand for more sustainable products and services.

Based on standards such as ISO 17065, ISO 17029, ISO 14065 and ISO 14021, these marks ensure your products meet relevant requirements and criteria. Choose from the following product attributes:

- Recycled content

- Product carbon footprint

- Carbon footprint reduced

- PFAS-assessed

- Biobased

- Hazardous substances assessed

- PVC-free

- Industrial compostable

- Biodegradability

More information is available at SGS Green Marks.

Technical construction file (TCF) review

Before shipment.

Ensure documentation is compliant and complete. We can help you review the technical files provided with your juvenile product (test reports, etc.) We can also check labeling to ensure that appropriate warnings, product and usage information and assembly instructions are provided to consumers.

Why choose SGS?

Global recognition. Global and local expertise.

Expertise

We actively support the safety standards development process by participating in several ASTM, ISO and EU work groups. Through our internal juvenile products technical committee, we ensure labs and technical experts are up to date with worldwide regulatory requirements and have harmonized test methods and interpretations.

French Decree 91-1292 type examination

In France, we have been approved to test to the French Decree on the prevention of risks resulting from the use of childcare articles and we are able to perform type examination.

Notified body status

In addition, we also have four EU Notified Bodies for toys in France, Germany, Netherlands and Turkey.

Training and webinars

We run regular webinars to help those in the juvenile product industry stay up to date with the applicable standards and regulations.

Our global network

Our laboratories are ISO/IEC 17025 accredited by ILAC signatories such as IAS (US), INMETRO (Brazil), COFRAC (France), UKAS (UK), CNAS (China), TAF (Taiwan, PrC) and VILAS (Vietnam), among others.