When you work in an industry that has traditionally been amongst the most dangerous in the world, you put safety first. In mining, the lives of your staff and your business reputation depend on it. But how can you avoid complacency slipping in, and ensure that protection for your work force is consistently everyone’s priority?

Looking for something specific?

Search within Mining

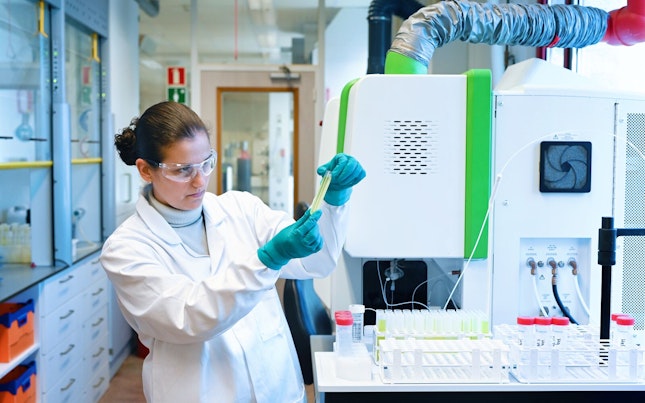

Safety training from SGS leverages our global experience as one of the leading testing and inspection companies in the world. We guide you to develop systems that offer proactive and effective risk management against recognized standards and allow you to manage hazards and human error.

Our expertise and methodologies use the latest technological industry advances and with laboratories and centers internationally, we offer services in remote and urban locations. With expert facilitators, we help you establish safety cultures based on trusted and dependable theory and practice.