We work with clients across multiple sectors, including food and beverage, pharmaceuticals, manufacturing, medical gas supply and energy.

Process gases are used in production and processing in many industries. Analysis and measurement of these gases is essential for ensuring safety, meeting process control demands and complying with regulations. We provide testing, analysis and certification services for industrial, medicinal and ultra-high-purity gases. This can include supplying custom analytical systems to enable continuous monitoring onsite.

What are the benefits of gas analysis services from SGS?

We enable you to:

- Ensure that your gas supply has been tested for quality and safety by an independent third party

- Comply with the latest industry standards

- Continuously monitor your gas supply on site, by providing you with custom gas analyzer systems and contracted testing solutions

- Trust an ISO/IEC 17025 accredited laboratory (INAB Registration No. 391T)

Our gas testing and analysis services

- Process gas testing

We provide onsite:

- Pharmaceutical gas testing, including testing of nitrogen, oxygen and carbon dioxide, in compliance with international pharmacopeia monographs

- Commissioning qualification and validation (CQV) of activities of pharmaceutical plants

- Raw material testing of gas supplies

- Routine monitoring of gas installations

- Testing and sampling of compressed air per ISO 8573

- Qualification of new gas storage, purification and distribution systems

- Sampling of industrial, medical and high-purity gases for all laboratory analyses

- Sampling of viable and testing of non-viable particulates content

- Sampling and site testing of hydrogen, up to fuel-grade specifications

- Analysis of carbon dioxide quality, up to food-grade standards

- Specialist laboratory analysis

We offer analyses of multiple gases, including:

- Testing to pharmacopeia standards (EP, USP and JP)

- ISO/IEC 17025 accredited for all methodologies in line with the ISBT Food Grade CO₂ standard

- Food grade CO2 testing to ISBT, EIGA, Pepsi, Coca Cola and Heineken standards

- Hydrogen fuel testing to ISO 14687

- Product testing and certification of industrial and medical grade gases

- Compressed air testing to ISO 8573

- Microbiological testing of compressed gases

- Complex gas composition analysis to customer specifications

- Ultra-high-purity gas analysis down to ppt level impurities

- Calibration and maintenance

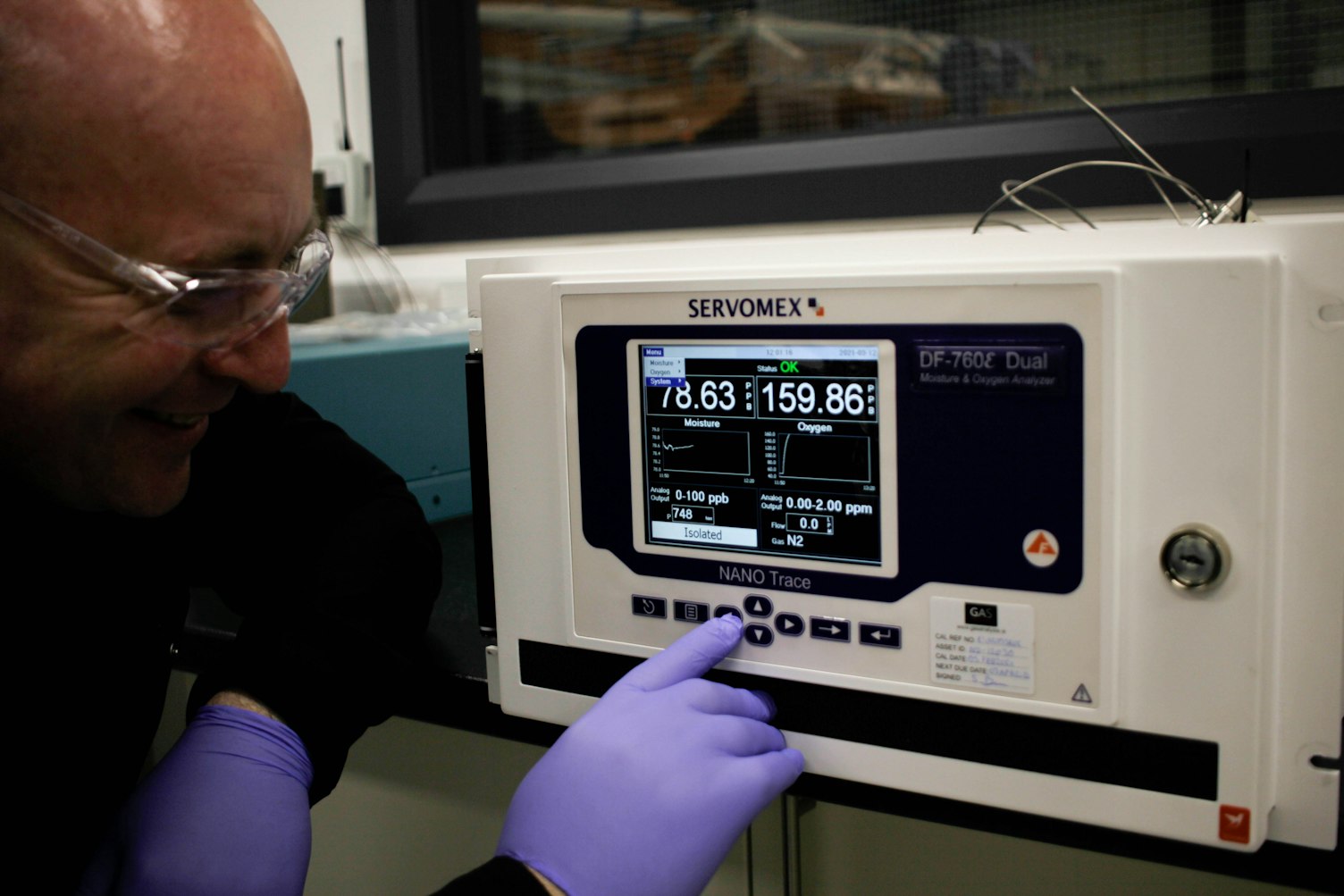

We have an inhouse calibration facility and an ultra-high-purity analyzer calibration facility. Our field services instrumentation engineers and contracted commissioning and project engineers, supported by our technical center of excellence in Ireland, provide:

- Onsite preventive and corrective maintenance

- Onsite calibration of gas detectors, gas analyzers and gas chromatographs

- Contract and project services

- Dedicated service and repair workshops

- Custom process measurement solutions

Our specialized team, which includes project management specialists, CompEx electricians, mechanical fitters, AutoCAD technicians and instrumentation engineers, provides:

- Design, assembly and validation of complex gas analysis systems

- Factory acceptance testing, installation and commissioning

Key applications:

- Insertion control systems

- Combustion control and emission monitoring

- Industrial, medical and UHP gas certification systems

- Process control gas analytical solutions

- Hydrogen fuel quality analytical systems

- Fully automated gas analysis systems for continuous monitoring

- Semiconductor gas line assurance

We provide UHP gas and chemical line testing for the semiconductor industry, including:

- Visual inspection of gas and chemical lines for facility and tool install projects

- Analytical testing for trace oxygen and moisture with ultra-fast response systems

- Analytical testing for non-viable particulate analysis with low-flow systems

- Inboard and outboard leak testing of UHP systems

- Report of failures and issues impacting construction quality

- Analysis of failure data and establishment of corrective actions

- Acoustic leak detection surveys for all gas matrices

Why SGS?

We have over 40 years’ experience in industrial gas testing and certification, with a global presence supported by our center of excellence in Ireland. As an independent third party, you can trust the accuracy of our quality testing of your gas supply. Our solutions are compliant with the latest industry standards. We have partnerships with major gas analyzer manufacturers and work with a wide range of industries, including pharmaceutical, biopharma, medical devices, food and beverage, semiconductor, hydrogen, transport, oil and gas, and aeronautics.

To learn more about our gas analysis services, contact us today.

FAQs

Please contact us directly via the contact button at the top of the webpage or reach out to your local SGS representative. We’ll provide a customized quote and schedule based on your specific requirements.

ISO 14644 is the international standard for cleanroom classification and environmental monitoring. Part 1 (ISO 14644-1) sets limits for airborne particle concentrations. In pharmaceutical production, process gases like compressed air and nitrogen must meet similar standards for particle cleanliness.

Yes. We perform ISO 14644-aligned testing for viable and non-viable particles in process gases, using particle counters capable of detecting and quantifying particles ≥0.5 µm and ≥5 µm, as required.

EudraLex Volume 4 outlines good manufacturing practice (GMP) for pharmaceuticals in the EU. Annex 1 specifically requires that compressed gases in contact with sterile products be regularly tested for both viable and non-viable particles to ensure product safety.

ISBT certification ensures that beverage-grade gases meet the strict purity and safety standards defined by the International Society of Beverage Technologists. It is required by major bottlers like Coca-Cola and PepsiCo, and other beverage producers worldwide.

Yes. Our ISO 8573-1 service includes testing for particles, water (humidity and dew point), oil content and microbiological contamination in compressed air systems.

It depends on your industry and risk level, but many companies perform testing annually or semi-annually. For critical applications like food, beverage or pharma, more frequent testing may be recommended.

A third-party QA/QC provider is an independent organization that verifies compliance against specifications or standards. In the semiconductor industry, third party QA/QC providers are critical for achieving the quality and safety standards required during construction and commissioning.

QA/QC verifies construction quality before energization, while process qualification validates that energized systems operate according to specifications. Both steps are critical for ensuring safety, quality and efficiency in semiconductor operations. We can mobilize specialized equipment for the process qualification of bulk gas installations (storage tanks, purifiers, filtration and/or distribution systems).

Downloads

Unit 1C N11 South Point Business Park, Charvey Lane, Rathnew, Co,

A67 P275,

Wicklow, Leinster, Ireland