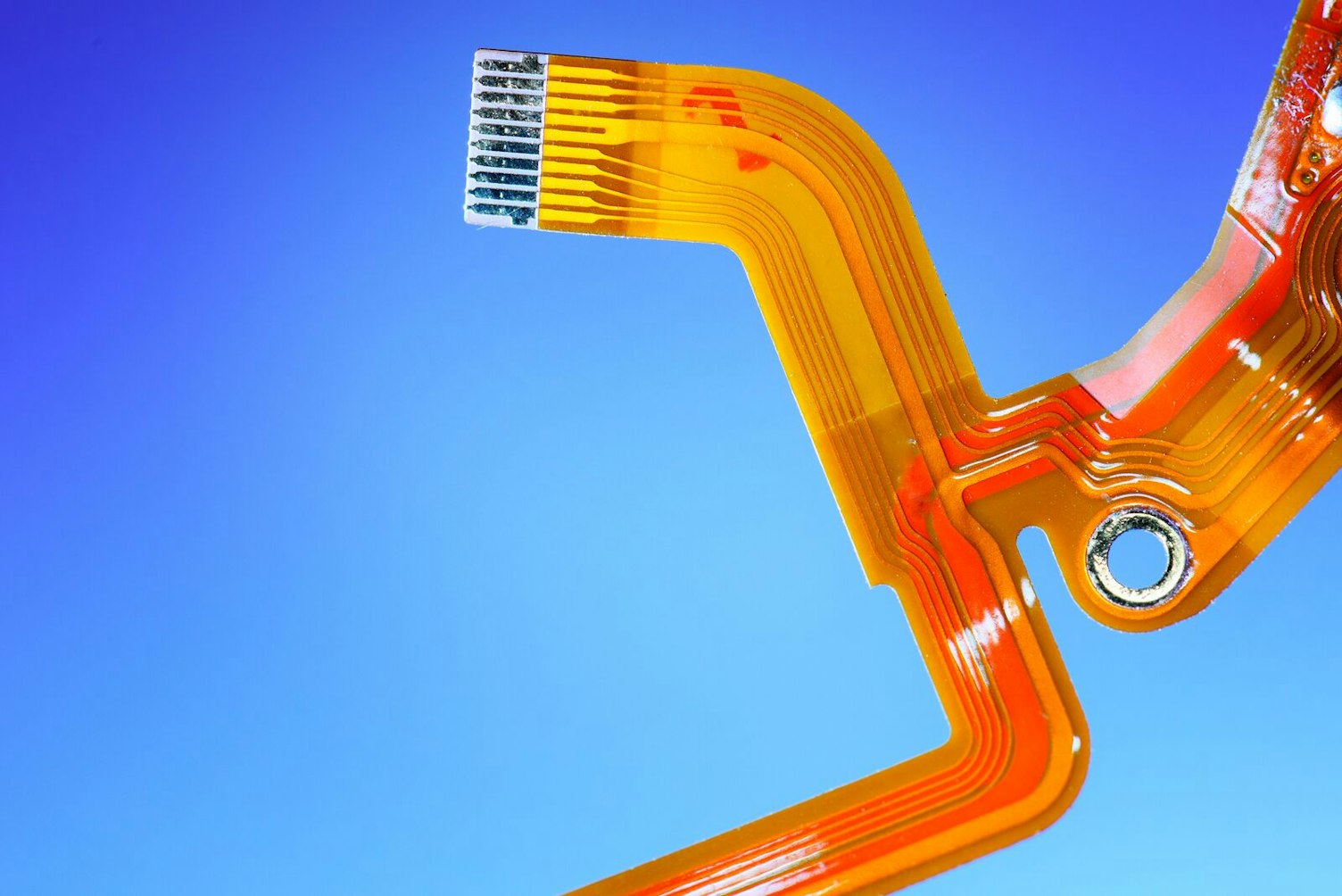

The market FPC products is growing rapidly due to the trend toward thinner, smaller electronic devices, especially in smartphones, wearable devices and automotive electronics. With increasing market demand, the performance and quality requirements of FPCs are becoming more stringent. We provide professional and reliable testing services, using advanced technology and equipment to help FPC manufacturers ensure product quality and meet market demand.

Ensure the quality and performance of your FPCs

We enable you to:

- Access comprehensive FPC testing

Covering all aspects of FPC quality – from visual inspection to voltage withstand tests.

- Improve product reliability

Identify and address potential issues early in the development process, ensuring high reliability and performance.

- Meet stringent market demands

Ensure compliance with industry standards and regulatory requirements, enhancing product reputation and market competitiveness.

Discover our FPC testing capabilities

We offer comprehensive services for FPC Group Tests TG1 to TG13. Our FPC testing includes:

- Visual inspection and dimension measurement:

Ensuring precise results

- Electrical testing:

Loop resistance, insulation, voltage withstand, and maximum current carrying capacity

- Thermal and environmental testing:

High-temperature exposure, temperature and humidity cycling, constant humidity and heat, salt spray, and low-temperature winding

- Mechanical testing:

Thrust test, peeling-force test, cross-section test and adhesion tests between various materials

- Reliability testing:

1008h current cycle, high-accelerated stress, vibration, bending and scrape abrasion

- Specialized testing:

Double-sided adhesive aging, NTC sealing, and tin whisker evaluation

We ensure compliance with the following standards:

- IPC610/IPC6013: GB/T 2423.17

- IPC-TM-650: USCAR2-6/USCAR37

- ISO6722

- QC/T423-2002: GBT2408-2008/UL94

- GB/T 11918.1

- GB/T 1040.2

- GB/T 9341

- GB/T 1043.1

- GB/T 1634.2

Why SGS?

FPC testing expertise and advanced techniques

As a global leader in inspection, certification and testing, we provide unrivaled expertise and advanced techniques in FPC testing. Our dedicated professionals and state-of-the-art facilities ensure accurate and reliable results, helping you to enhance product quality and performance.