February 08, 2024

SGS has added a new technique to their non-destructive testing solutions for their oil, gas and energy sector in the United Arab Emirates. With the introduction of Magnetic Flux Leakage (MFL), our inspectors based in the UAE will be able to identify the depth of wall thickness caused by corrosion and erosion.

Pipes are crucial for various oil and gas functions such as refineries, exploration production, transmissions, fertilizers, chemicals and associated fields. Their ultimate purpose is to safely transport the substance from one location to another without incident. However, while they are in use, periodic maintenance is required to ensure its still working to its abilities. The rise of non-destructive testing (NDT) methods allows inspectors to test the pipes without compromising the supply chain process.

Pipes are crucial for various oil and gas functions such as refineries, exploration production, transmissions, fertilizers, chemicals and associated fields. Their ultimate purpose is to safely transport the substance from one location to another without incident. However, while they are in use, periodic maintenance is required to ensure its still working to its abilities. The rise of non-destructive testing (NDT) methods allows inspectors to test the pipes without compromising the supply chain process.

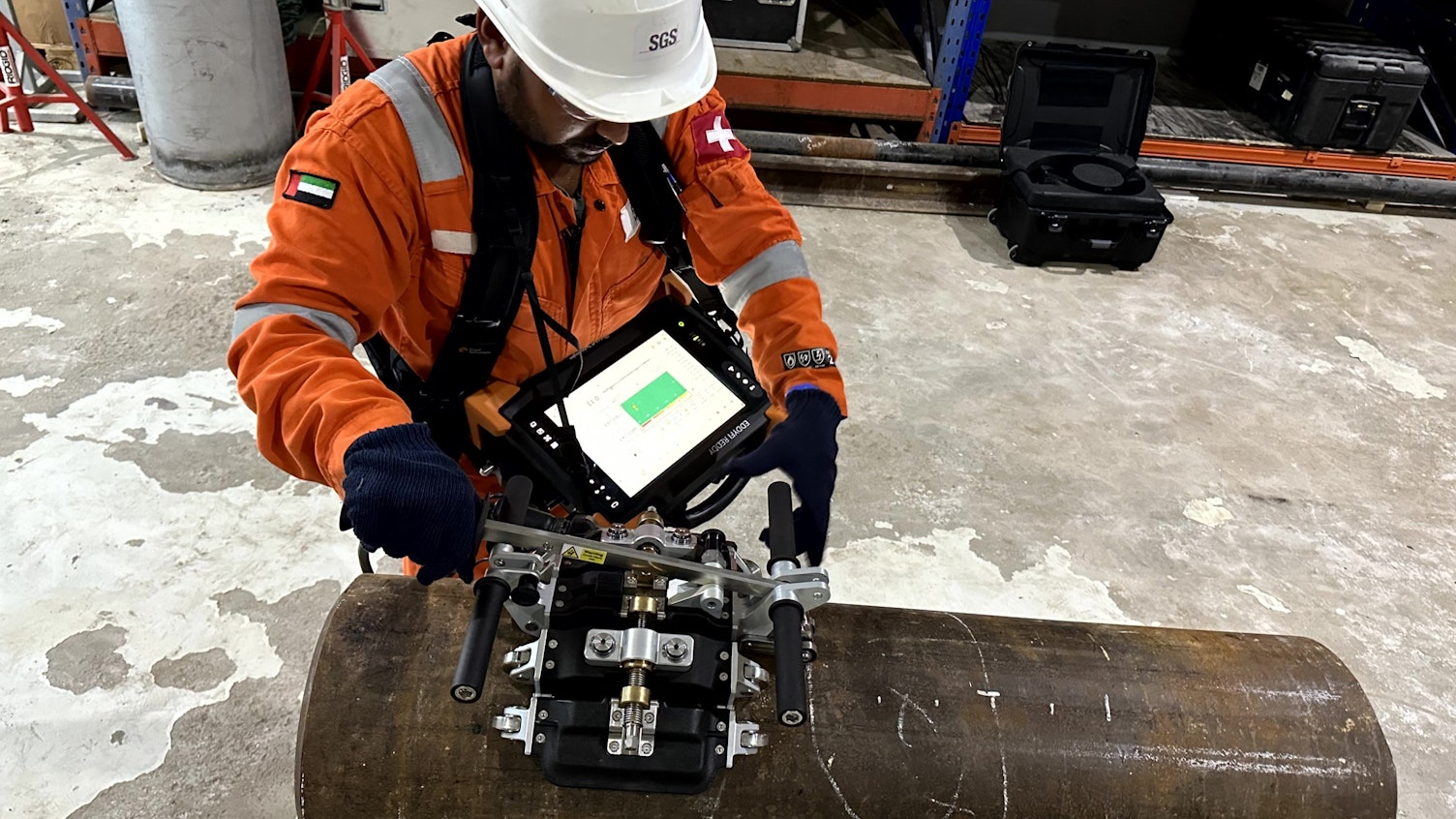

Magnetic flux leakage is an NDT method that’s used to detect corrosion, wall loss and erosion in steel pipelines. To accomplish testing, a scanner called the Pipescan HD is used for inspection of pipe work ranging from 127 mm to 12 cm diameter. It works by inducing a strong magnetic field, to create saturation. After this process, leaks and flux will be sent to the sensors for measurement capture. The scanner records data from the moment it interacts with the pipe and the reports are instantly generated.

Non-destructive testing helps operators deploy integrity assessment programs through periodic inspections and data collection to ensure operational safety in a timely manner. Our team does due diligence to identify potential problems, understand their severity and how to mitigate them. This reduces costs for organizations and ensures the pipes are running safely and effectively for longer.

SGS continuously enhances its services and applications with new cutting-edge technologies and has always executed a solution-based approach. Implementing integrity assessment programs for organizations include a combination of techniques that target the necessary equipment and challenges.

Our team’s integrity and reliability are built through robust inspections that utilize state-of-the-art equipment, certified and experienced personnel, and specialized technology such as advanced imaging and analysis software.

Non-destructive testing helps operators deploy integrity assessment programs through periodic inspections and data collection to ensure operational safety in a timely manner. Our team does due diligence to identify potential problems, understand their severity and how to mitigate them. This reduces costs for organizations and ensures the pipes are running safely and effectively for longer.

SGS continuously enhances its services and applications with new cutting-edge technologies and has always executed a solution-based approach. Implementing integrity assessment programs for organizations include a combination of techniques that target the necessary equipment and challenges.

Our team’s integrity and reliability are built through robust inspections that utilize state-of-the-art equipment, certified and experienced personnel, and specialized technology such as advanced imaging and analysis software.

Our commitment to obtain up-to-date knowledge and its implementation has made SGS a trusted service. We look forward to continuing our work in pipeline integrity assessment projects.

About SGS

We are SGS – the world's leading testing, inspection and certification company. We are recognized as the global benchmark for sustainability, quality and integrity. Our 99,600 employees operate a network of 2,600 offices and laboratories, working together to enable a better, safer and more interconnected world.

Floor No.1, Building No.340 Street 230, Zone 24,C Ring Road,

24140,

Doha, Qatar