During the lifetime of a vehicle, its components, parts, assemblies and sub-assemblies will need to withstand repeated usage as well as conditions including stresses, strains and temperature changes. For this reason, original equipment manufacturers (OEMs) demand the highest quality components throughout the supply chain.

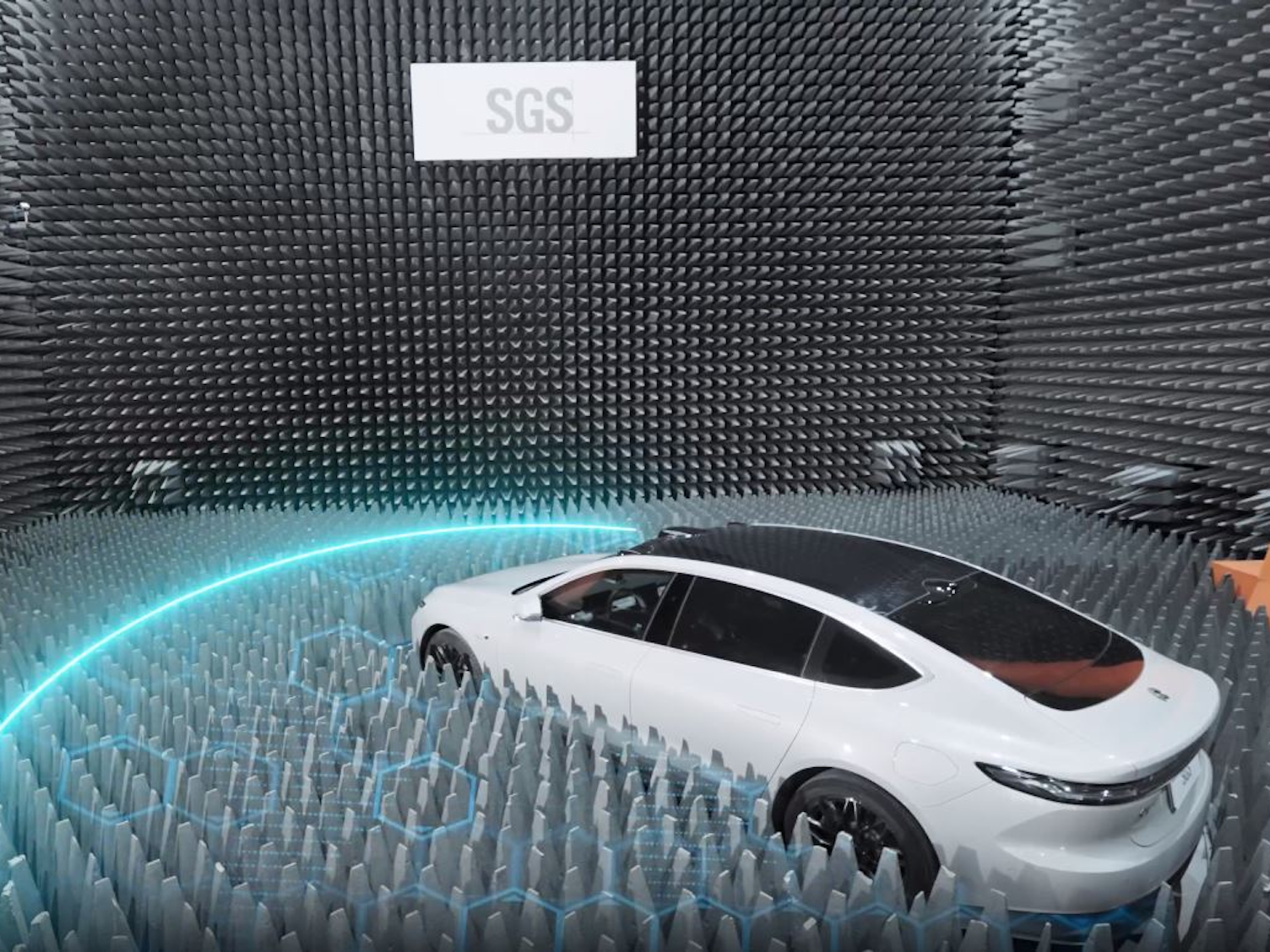

At SGS, our endurance and durability testing services can verify these high standards and help OEMs determine the expected life expectancy of components, as well as the long-term viability of the car. Testing during the early stages of product development also detects faults before the vehicle goes into production, saving time and costly recalls.

We have the experience, equipment and expertise to test full vehicles, subsystems and individual components against OEM national specifications such as ASTM, DIN and JASO, as well as international standards including ISO, EN and SAE.