Root Cause Failure Analysis (RCFA) is an important part of the Asset Integrity Management service package offered by SGS. Recently, our team from SGS Pakistan has completed an RCFA assignment for a leading solution provider to Oil & Gas industry in Oman.

Bolts failure leading to a number of challenges

A major Oil & Gas solution provider in Oman was facing problem in their operation / production after breaking-up of three major bolts. The bolts failure was reported during service / operation. Failed bolts were installed with compressor support at plant.

Observed bolts failure resulted in:

- Production deferral / downtime

- Significant compliance concerns related to service/operational integrity

- Health and safety implications for employees

- CAPEX increased for new bolts replacement

The company decided to apply to SGS experts for identifying the root cause of this operational failure.

Objectives of the assignment

The Omani company asked SGS:

- To visualize and examine current condition of their operation, MTCs and failure history for the identification of non-conformities in accordance with international standards or best engineering practices,

- To propose recommendations for the prevention / mitigation of the observed damage.

SGS team opted for the RCFA methodology to achieve the set objectives.

What was done by SGS

SGS thoroughly reviewed, examined and analyzed provided documents and failure history from client to visualize basic insufficiencies for further investigation.

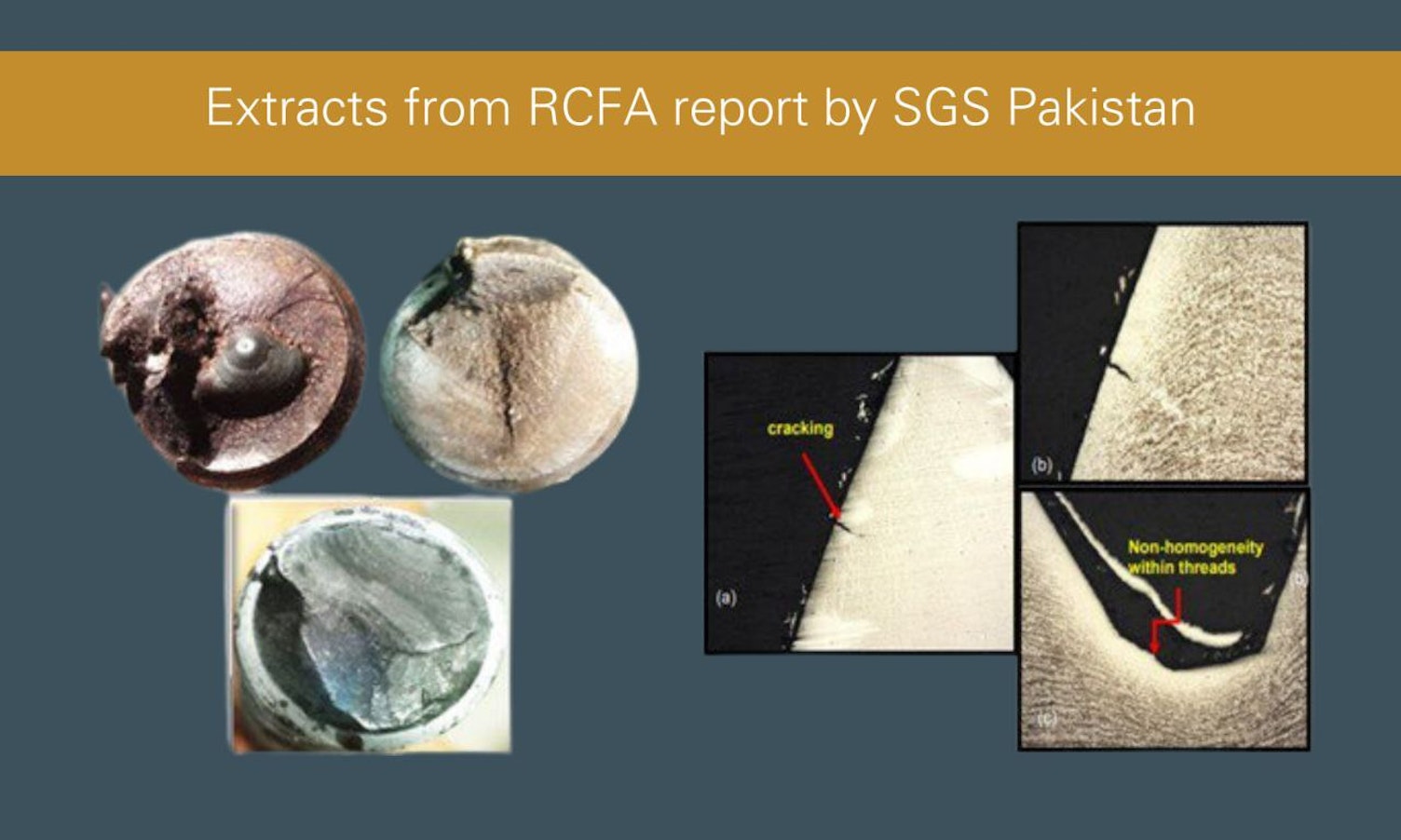

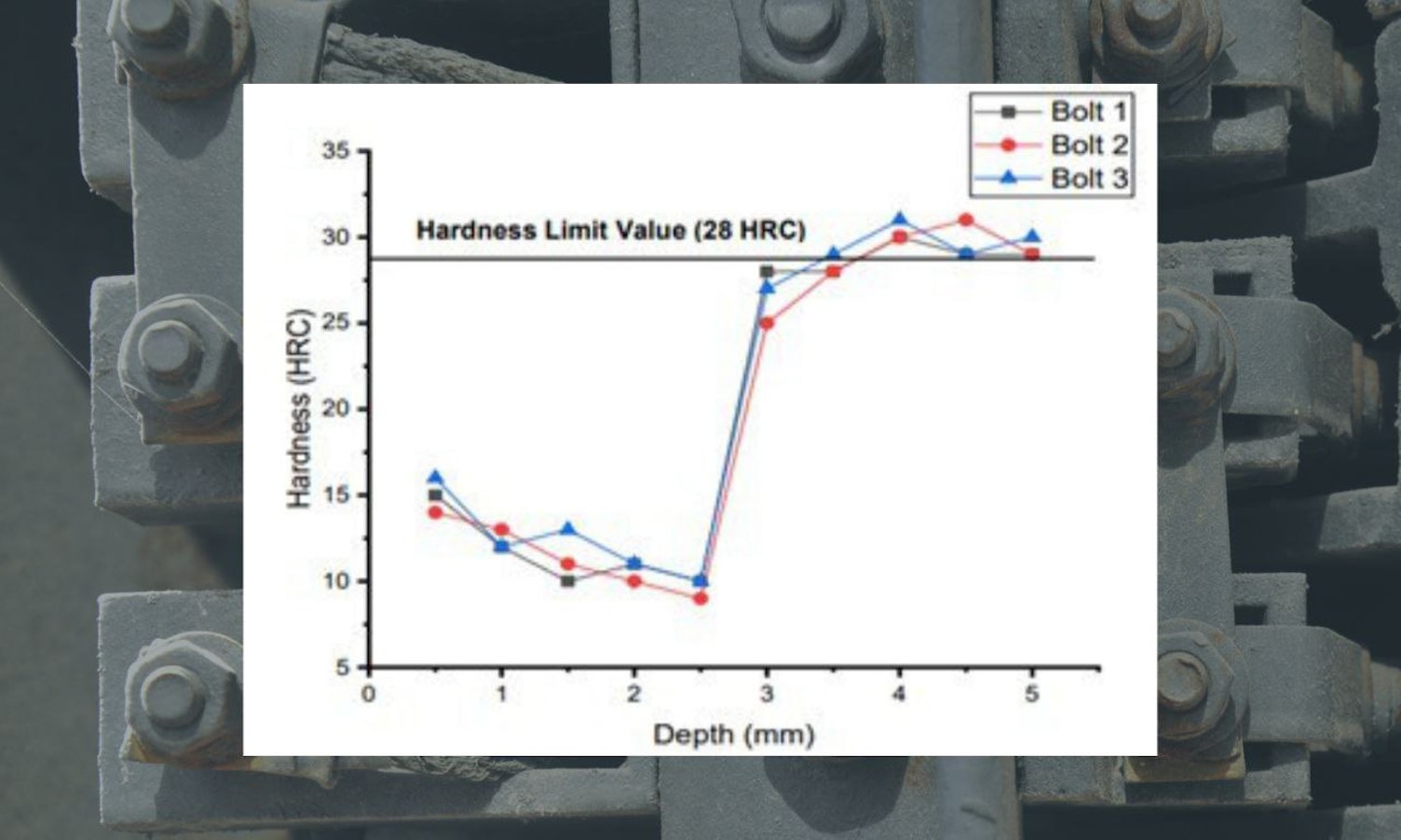

A series of forensic analysis has been performed on multiple samples extracted from near and away from failure region of damaged bolts for comparative analysis.

Based on the investigation carried out and the evidence obtained through visual examination, hardness testing, and fractography on broken bolts; it could be concluded that bolts failed by an unidirectional bending fatigue failure mode. Failure of the bolts were initiated by high vibration and occurred due to synergic effect of tool / wear damage and improper hardening heat treatment.

Benefits of the RCFA methodology

You can solve a problem only in case you fully understand its roots.

After learning the reason of bolts failure and identifying operational risks, the Omani solution provider could take relevant measures in order to prevent the failure from recurring and enhance future asset reliability.

Ultimately, it will save future capex (i.e. new asset installation, hazards etc) and will turn down employee health & safety risks.

Conclusion

Root cause failure analysis is a roadmap to prevent future failures, optimize your operation, and drive your business towards greater success. Our team of expert analysts specializes in uncovering the root causes behind failure, leveraging cutting-edge forensic methodologies. We'll work closely with you in examining every aspect of your processes and leave no stone unturned.

Together, we'll conquer failure and pave the way to excellence!

About SGS

We are SGS – the world’s leading testing, inspection and certification company. We are recognized as the global benchmark for sustainability, quality and integrity. Our 98,000 employees operate a network of 2,650 offices and laboratories, working together to enable a better, safer and more interconnected world.

Building Office: 31/32 -256, Road 3605 Area 336,

P.O. Box 26340,

Adliyah, Bahrain